How To Jibe a 505 From the Front of the BoatBy Jesse Falsone, USA 505 8722

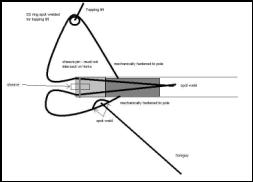

A Good Pole Launcher System

A good pole launcher system is one that works each and every time you jibe and on both tacks. I like to have 4 passes of 1/4" shock cord on the pole retrieval. Make sure there's the least mount of friction possible in the system. The blocks should be right-sized, there should be no chaffing with other lines or shock cord in the boom, and the shock cord should have ample elasticity. Having the exit block on top of the boom can help (rather than on the side). Periodically check for shock cord tension before going sailing, and snug up on it occasionally (cut excess off to avoid fouling).Another must-have on a pole launcher system is a "pole retractor shock cord". This system will pull the pole off the mast fitting when the pole launcher line is uncleated. This is very easy to rig. Simply use a single pass of 3/16" cord that dead ends at the aft end of the boom, runs forward through a small block at the front of the boom, and is tied around the pole with a loose bowline.

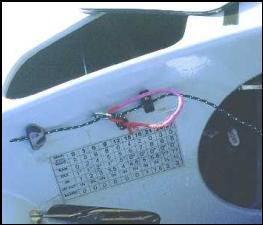

For my pole launcher cleat, I prefer the small Harken SS swivel. This cleat has a large sheave, a stainless body, and is more reliable than the Ronstan equivalent. The only downside is that you can only mount facing up, so you always uncleat going up. The good thing about this is that you will never accidentally uncleat it while stepping in the boat and onn the pole launcher line. The problem with the Ronstan is that it's all-plastic construction wears as the line passes over it, and over time, the line can actually get caught between the cleat and the cleat body. There's also a bit more sheave friction with the Ronstan. Another trick on the pole launcher cleat is to have a piece of shock cord going from the cleat up to the boom. This keeps the jib sheets from wrapping around the cleat through a tack.

I prefer 5mm Marlow pre-stretch for the pole launcher line. This line is strong, fairly wear resistant, holds well in the cleat, and doesn't kink like some high-tech line. It's also cheap. The fact is that there's little tension in this line once the launcher is seated in the socket. I like enough extra line to allow for a 1’ tail so it’s easy to grab coming out of a jibe.

There's on-going development on pole fork design now. The current thinking is that you need a "larger target" on the forks - that is to say that you need longer forks to facilitate putting the guy in the forks through a jibe. I can say that this is true, and an experienced crew will only occasionally get delayed on a jibe because the pole forks are too small and he can't "find" them fast enough. There's also talk about integrating a sheave in the pole forks to allow the pole to run forward quickly and easily. Mike Martin is always fooling with pole fork designs. His forks have a longer plastic cap with a steeper angle (rather than the round end cap). This type of arrangement allows for less friction as the pole slides forward on the guy. There's more talk about inserting a small, stiff rod inside the topping lift where it connects to the pole to keep the t-lift from wrapping around the pole (this happens sometimes).

The fork tension should be enough to keep the guy in the forks in light downwind conditions, but loose enough to allow the guy to come out through a gybe. I have found that the guy will get hung in the forks occasionally in light air when there's little tension in the guy. This is probably the best trade-off. You can help this situation in light air downwind jibes by blowing the twings before the pole.

A Good Twing System

A good twing system will work each time you pull it, will always come all the way in, and will cleat well. You should have just enough twing line to allow the spinnaker sheets to go all the way up, but this amount seems to vary on spinnaker design. I prefer the Martin-style two-handled single-pull twing system. It’s an easy system to rig, but more difficult to fine-tune. First, I use 4mm Marlow pre-stretch for the twing line, but some people use other stuff. I prefer to sew the ends around small stainless steel rings, but some people simply tie them. I like 3/16” handles with some plastic tubing on them to make it easy to grab and hold. The handles are sewn around 1 ¼” stainless rings that the twing line passes through. I prefer shock cord to hold the handles into the bulkhead.

Before Jibe

Crew should be conscious of what I call "sheet management". This is simply the arrangement of the spin sheets, the jib sheets, and the pole launcher line in relation to the crew's feet. I like the spin sheets aft of my back foot, the jib sheet forward of my forward foot, and the pole launcher line trailing overboard between the windward shroud and the trapeze shock cord. The skipper should simply hand the pole launcher line to the crew after each wire-to-wire jibe, and the crew should throw it overboard. The skipper should also pre-cleat the windward jib sheet, taking all the slack from it. This prevents the jib from wrapping around the forestay.

Getting Ready To Jibe

You've decided it's time to jibe. The skipper should have the boat at maximum speed and going down a wave if possible. The crew should check his "sheet management" situation so he doesn't get tangled up.Going Into the Jibe

When the boat is at maximum speed, the crew uncleats the jib, unhooks from the wire, and swings in so that his back foot goes over the CB trunk and he is facing forward straddling the trunk and just aft of the thwart. As the crew swings in, he must be focussing on the pole launcher cleat so he can break it off as soon as possible. The skipper should cue on keeping the boat flat at this point! This is a key point. When it's windy, the skipper will bear down harder to keep the boat flat. When it's less windy, the skipper will not turn down too much. In all cases, the initial turndown should be smooth to avoid throwing the crew around.Blowing the Pole

The crew blows the pole. The skipper should not jibe the boat until the pole is blown AND coming back fast. This is another key point. If the pole launcher system is working properly, the pole will shoot back, the guy will release from the forks, and the boat will be flat. If the pole is not working properly, it may not come off the mast, come back too slowly, and maybe not release from the forks. In this event, it's best to wait for the crew to QUICKLY sort out the mess before turning the boat. Typically, a pole launcher will always work better going from starboard to port jibe because the pole naturally wants to come back on the port side of the boom (leeward side in this case). While jibing from port to starboard, the pole can more easily malfunction since it has to basically overcome gravity if the boat is heeling to go to the windward side. The key here is to have a good pole system (see above).Throwing the Boom

Now that the pole is on it’s way back, and heading for the helmsman’s teeth, the helm should take that as his cue to turn the boat through the wind and DUCK! The crew should take his inboard hand (old aft hand), grab the vang, and throw the boom over. While completing this throw, he should grab the twing line and pull as he ducks the boom and pops up to the windward side. Give the twings a good pull to ensure they all slack is out.Guy in the Forks!

After pulling the twing, simultaneously pull the pole launcher line out about 1 foot with your new inboard hand, and grab the new guy with your outboard hand. Take the guy between your index and middle finger, and jam it into the forks. This is where a “larger target” really helps.Re-Launch the Pole

After you get the guy into the forks, slide your outboard hand back on the guy a bit, grabbing the guy firmly. With your inboard hand, give an initial tug on the launcher line while holding the guy. This allows the pole to more easily slide forward to the clew. Then, get the pole out fast hand over hand with big pulls. You should tag the skipper every once in awhile if you are doing it right ; ). The pole will seat itself with a thump onto the mast fitting.Grab the New Sheet and Get Out!

The skipper should be holding the new sheet on the leeward side for you, pre-trimmed. Scoop your inboard hand back and grab it (if you’re good, you can do this without looking). Then, with your outboard hand, grab the trapeze ring and fall into it with your trapeze harness. You can only do this technique IF the ring is at the right height. If the ring is too low, you can’t do this, so make sure your rings are pulled up a bit from going upwind. As you hook in, turn your body and fall out on the wire.Re-Trim and Re-Set

Now that you’re back out on the wire, re-trim the spin sheet and the jib sheet. Once you’re settled, have the skipper hand you the pole launcher line and pre-cleat the jib sheet so you’re ready for the next jibe!

How to Gybe a 505 By Barney Harris