The Van Munster 505

Since the World Championships in Portugal there have been several adjustments made to our tooling system.These modifications have been made in consultation with Current World Champion Holger Jess and 5 times World Champion Krister Bergstrom. We have designed and manufactured a series of inserts to our tooling system that allows owners to semi customise their boat setup and layout by the combination of our standard mouldings with the new inserts to achieve a personalised boat layout.

Modification includes the option of a new longer centercase trunk.

Two mast step heights.

Longer mast gate and low mast step allows rig to be stepped at class max aft.

A customised female moulded carbon fiber bar can now be retro fitted for helmsman that want to use an adjustable mainsheet bridal system for mid boom sheeting. The bar is wide enough to allow small cam-cleats to be mounted on the bar.

A custom made jib turning block can also be fitted to the bow to allow the forestay adjustment to run through a mandril spun carbon tube in the fordeck section into the cockpit.

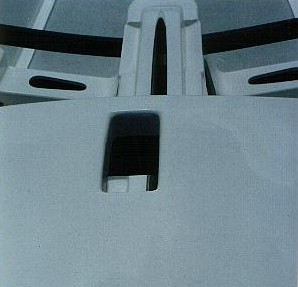

A carbon fiber recess can now be laminated into console to allow jib cleat to be mounted flush with the thwart further cleaning up the cockpit while making the cleat less obtrusive to the forward hand in light winds. For more information contact Brett Van Munster [email protected] Van Munster Boatbuilding

New hull shape

Van Munster Shipwright & Boatbuilding, at Narara, NSW, has built ten boats from a new female mould. The mould is constructed from a low shrink polylite tooling system that enables elevated temperature curing during construction. The low movement and shrinkage properties of this system allow accurate reproduction of a hull shape that takes full advantage of class tolerances.

The original plug, based on the successful Kyrwood hull shape, was altered during construction of the new tooling. The alternations included straightening the stem and flattening the spring. This has produced a finer entry to the bow section, Van Munster says.

Subtle modifications have also straightened the buttock lines, providing a flatter run aft and a slightly softer turn of the bilge. These changes reduce wetted surface area and maximize the waterline length.

The centreboard case has been modified to allow the latest generation of high-aspect gibing boards to fit into the smallest possible centrecase. The centercase slot has been shortened and the volume minimised in an effort to increase the buoyancy of the hull.

Nine of the new boats are of vacuum-bagged carbon composite construction – extremely stiff and light in the ends. The deck weighs less than 22 per cent of the boat’s finished sailing weight. Bare hull weight is 83kg and some of the carbon boats are carrying up to 15kg of lead to bring them up to sailing weight.

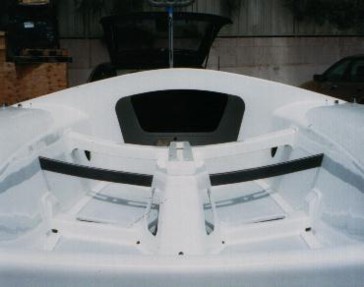

The cockpit layout of the Van Munster boats has been re-designed to provide the crew with a clean and simple work area. The smaller centerboard console allows find-tune systems to be led straight to the helmsperson while in the normal hiking position, helping “gear changing”.

The console design allows for the fine tune purchase to be contained close to the centrecase.

March 16, 2002

The following is some information on our

latest little project which may be of some interest.

Hopefully we should have some more comprhensive information and pictures within the next

couple of weeks.

As mentioned we are very excited about

the new prepreg carbon/nomex boats.

So far the constructed components are lighter and stronger than any of our previous boats.

As always it has taken some time to get the pre-preg up and running as their has been many

technical issues to overcome due to the processing temperatures of the pre preg and the

complexity of the 505 mouldings .

We have chosen to go with SP systems.Their pre pregs have been specifically developed for

high tech grand prix boat building such as Americas cup/ Volvo. Due to their involvement

in these types of projects they have established the best product, technical support and

knowledge of this of pre-preg boat construction. SP systems Aus have been fantastic in

this respect and have helped us with everything from laminate schedules, structural

analysis down to "hands on" laminating the first deck which is for Chris

Nicholson.

The hull and deck components are laminated with SP systems SE 84 prepreg. We are using

plies of 150 (HEC) uni carbon laminated either side of a 8mm phenolic coated aramid base

honeycomb core. Two plies of uni carbon are typically laminated in 0/90 direction through

out the hull and deck components to give a 300gm/sqm skin thickness. Areas of high stress

and impact such as the floor area along the centercase, mast step. The mast gate and top

of the tanks also have additional plies of uni carbon that significantly build the skin

thickness, strength and stiffness into the components. The bulkheads, spinnaker chutes,

centercase console are all wet laminated out of Sp systems latest generation Ampreg 22

resin with a combination of uni directional carbon/ twill weave carbon/ cotech +/- 45

double bias cloths. Divinycell closed cell foam is used in the bulkheads and console.

As you can see, only the best materials available are being used in the construction of

these boats. The combination of the best materials and the associated processing

technology of the epoxy prepreg produces components that are extremely light, stiff and

strong.

Calculations suggest that the expected bare hull weight to be around 65kgs (this is

actually a conservative estimate as the first deck weighed in 5kgs less than the original

calculations upon release from the deck mould).

The major weight savings of the pre preg construction over conventional wet laminate boats

are made in:

higher fibre/resin ratio, core and corebond adhesive and gelcoat.

Because we have not yet finalised bill of materials, costs of spray painting or labour

content of the prepreg construction it is difficult to give an exact quotation on the

final price.

I will endeavour to keep you updated on the progress of the new boats and send some

pictures of construction and get a price finalised ASAP.

Regards

Brett

Van Munster