| Rigging the Pump Spinnaker Halyard by Peter Alarie The "pump" spinnaker halyard is an alternative to the 1:4 system that became popular with the advent of bag boats. Both systems allow you to get the chute up faster than pulling it 1:1, but each system has its ups and downs. Traditional 1:4

You generally have to come off of the windward rail to be able to pull the line hard enough. Pump System 1:2

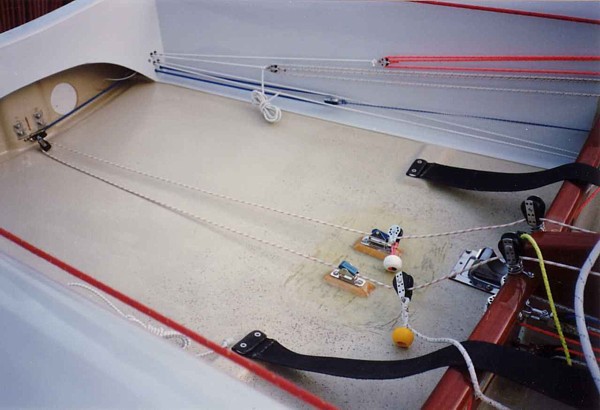

The basic plus of the Pump is that the skipper can sit on the rail and still pull up the chute. This is great on reaching sets and allows you to hang in a higher line. The system only requires one hand to pull, so you can drive and pull: crews dig this. While critics will say that the chute goes up slower, there are undeniable advantages to being in the high lane on the set. Also, one look at the ultra-competitive 470 class shows that almost 100% of the top boats are using the pump. So how do you rig it? The basic concept revolves around the Northfix fitting. This fitting is basically a one way switch that locks up the tail of the halyard when you pull on the handle, allowing you to pull up the sail up 1:2. When you release the handle, or "pump" it for another pull, the shock cord take up pulls the slack out of the halyard through the Northfix. When you pull again, the Northfix locks the tail again. Our halyard comes down the side of the trunk, goes through a small Harken cleat, bullet block on a pad eye 3" behind the cleat, bullet block floating with a handle (this is what you pull on), and then through the "Northfix" fitting which is about 2" behind the fixed bullet. On our boat, these fittings are all together on a wood block mounted to the floor. You could also figure out how to mount all of this to the CB cap, which might actually make it easier to use. The halyard then runs aft to a fixed, double bullet and then forward to another floating double bullet (which the shock cord is attached to) . Run the halyard through these blocks, making a 4:1 purchase and then dead end the tail somewhere aft. The shock cord take up needs to have a lot of throw and a lot of power. Our system is rigged with about 15-20’ of fat ¼" shock cord, dead ending at the thwart, going to the transom, back to the thwart, and then back to the transom where it ties onto the take up block (double bullet). Handle down towards the cleat, the shock cord system pulls the slack out of the halyard, allowing you to take another pump. Repeat until the sail is up, usually 2 ½ times. It is a little complicated and has taken us awhile to get right, but it has been worth the effort. If you learn from our mistakes, you should be able to get very close on the first try. Problem areas:

Peter Peter Alarie and Mike Zani won the 1997 North American Championship in their recently rebuilt and rerigged Lindsay 505, 7318. Earlier they won the '97 Midwinters. Peter is a partner in Guck, Inc. a Rhode Island custom boatbuilding company.

|

||||||||

|